Automation and robotics offer a comprehensive solution from the first workplace concept, through the 3D study, the production of equipment to the final validation at the customer, followed by professional service. Depending on the degree of automation, our workplaces and lines are designed as automatic or semi-automatic. As part of the device development, we put emphasis on functionality and security of the solution.

Keri a.s. Turnov

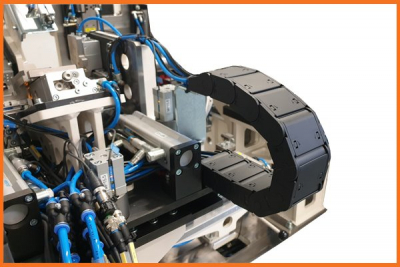

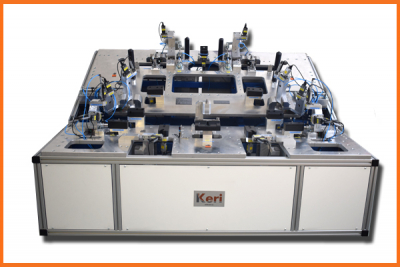

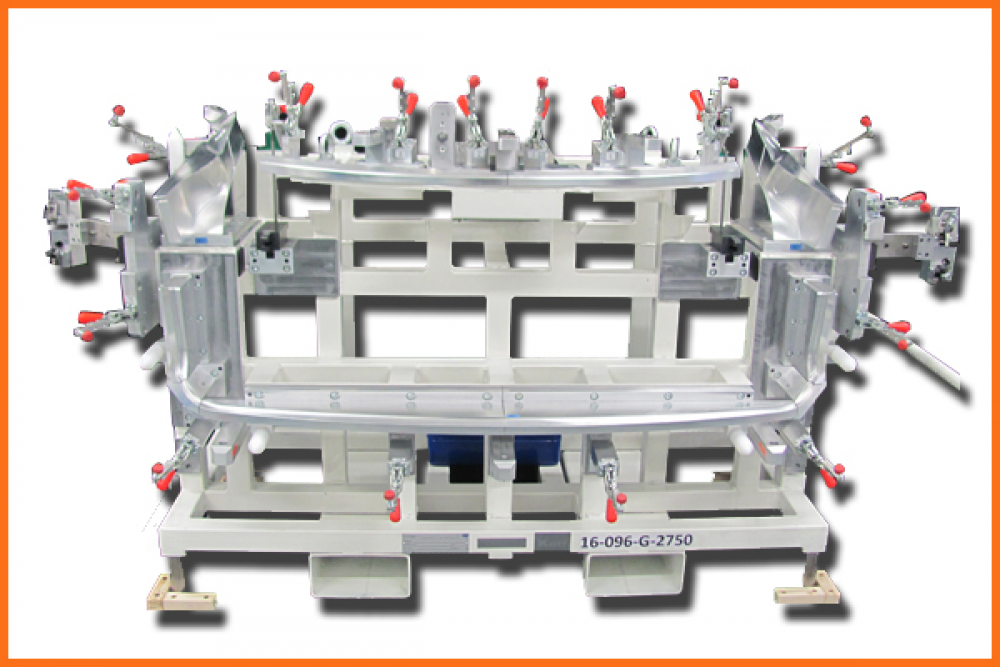

Assembly Fixtures

Assembly fixtures are used for completion of parts into assemblies. They can be equipped with pneumatic or electrical elements, if required. These devices may be used in production lines or as separate workplaces.They can be equipped with elements for presence checking of individual components, white the assembly may be performed as Poka Yoke.

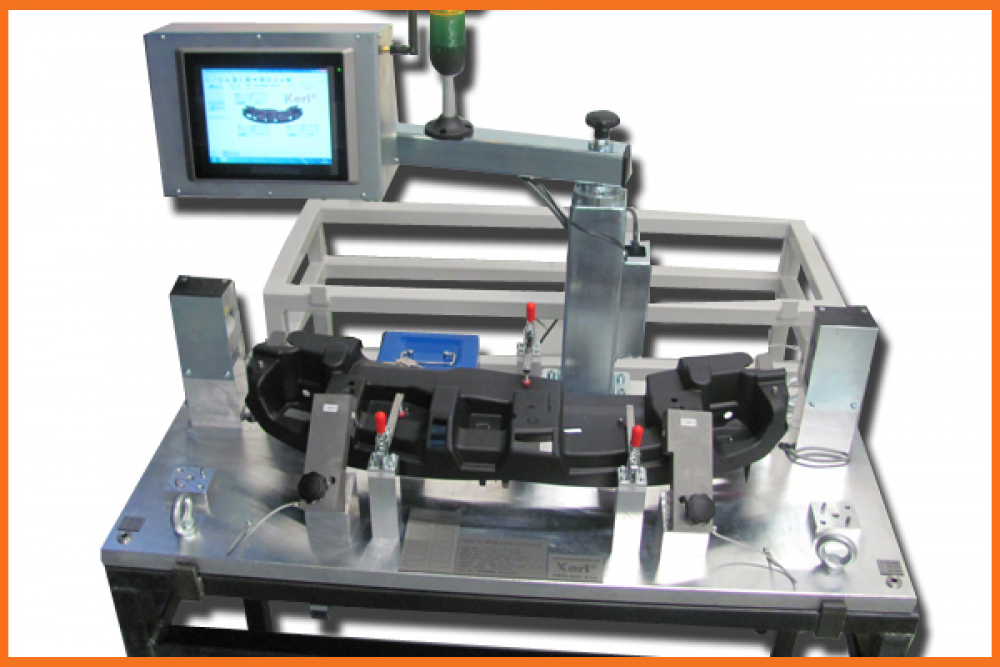

Laser Checking Fixtures

Laser checking fixtures are used to detect the value of deviation from the nominal (CAD data) by optical sensors. Accuracy of this solution is equal or even better than the one of a mechanical contact of common dial indicators - depending on the type of the sensor used. Currently, we can replace all surface surface and trimmings measurements, which are usually applied to standard checking fixtures, with laser measurement solutions.

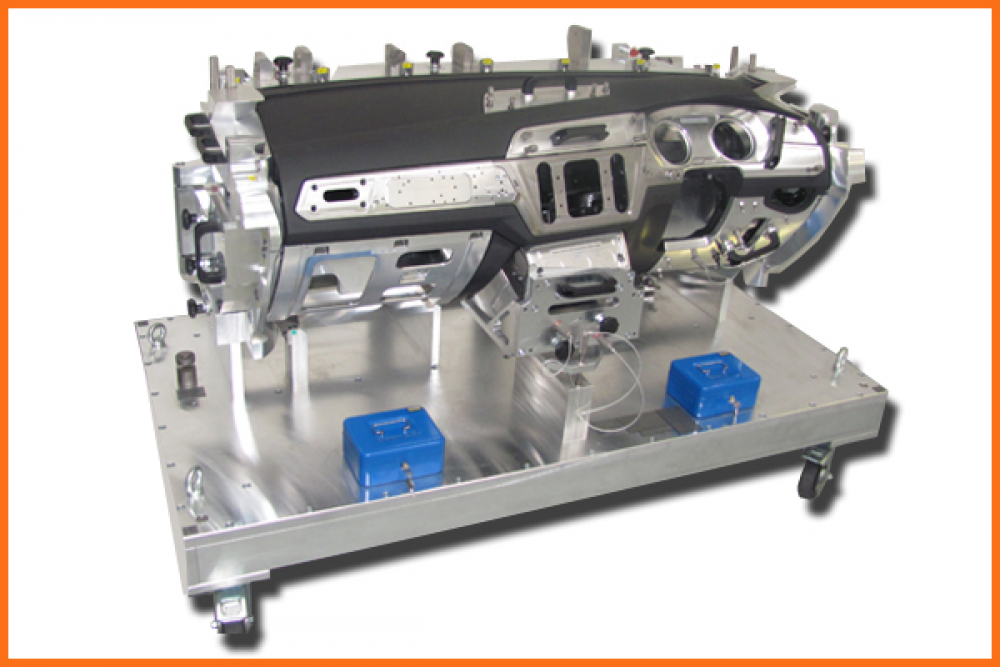

Cubings

Cubings represent measurement devices with a precise milled surrounding simulation of the part or assembly to be controlled. The part orientation is usually the same as in the real vehicle. The parts are inspected mainly visually and functionally. Cubings, however, can be equipped with any measuring instruments like general checking fixtures.

Checking and CMM Fixtures

Checking fixtures are used for a complete dimensional and positional check in the manufacturing process. The base is usually an aluminium board with steel parts, equipped with centering elements and fixations to enable part positioning in space according to the RPS coordinates. Measurement devices: dial indicators, rulers, GO/NOGO calibres, feeler gauges, sensors etc.

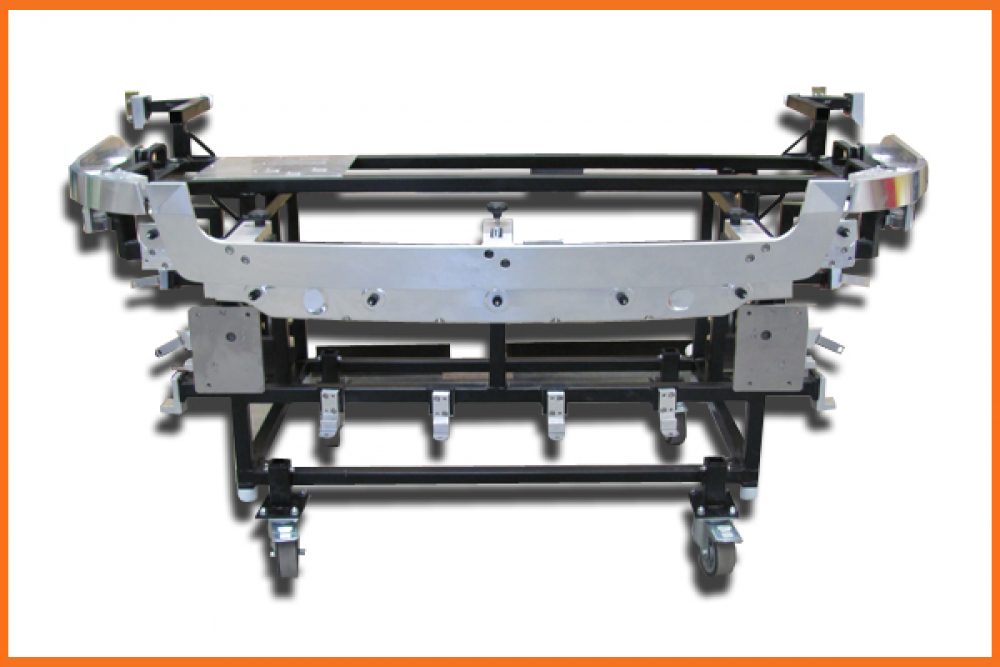

Testing fixtures

Testing fixtures are special gauges designed to tes automotive parts in climatic chambers where weathering aging tests are performer. In addition, gauges for impact test (PENDL) for checking the integrity of assembly parts (bumpers), deformation and safety, ag in the event of a collision with a pedestrian.